Introduction

On this page we will discuss the technology and benefits of Mac Pulse Valves for pulsing on dust filter installations. Focused on the savings you can make by using pulse valves. We will discuss the comparison with other construction valves and the advantages of the dust filter installations in your factory. We only discuss dust filter installations that work with compressed air-controlled valves. The Mac Valves Pulse Valves consist of a range of drop-in solutions for existing and new installations.

Advantages of Mac Valves Pulse valves

We will go through all the benefits in detail on this page. Do you want to go straight to a desired part? Then click on one of the links below. The advantages of the Mac Valves Pulse valves are:

- Energy saving

- Uptime

- Less maintenance

- Product efficiency

- Longer filter lifetime

- Easy use and installment

- Green impact

Firstly, discuss how Pulse Jet Baghouses work. Or go straight to Energy saving. Mac Valves Pulse valves are a widely used technique compared to the past.

Pulse Jet Baghouse

A Pulse Jet Baghouse is a Pulse Jet Filter installation. This is an installation consisting of a vacuum pump that sucks air from a production process or production environment. This air is sucked in and drawn through filters, causing the product to stick to the filter and the clean air to flow to the vacuum pump. As more and more product adheres to the filters, it becomes more difficult for the vacuum pump to suck in the air. At this time, the Pulse Jet system activates and the dust filter valves in the form of pulse valves will provide an air pulse with compressed air.

The valve blows air into the filter bags through a venturi effect or direct blowing into the nozzles. One valve fills several filter bags via a distributor. With the help of this air, the filter bag expands and the moment the pulse valve closes the air supply, the filter bag empties.

Because the filters inflate and deflate, a sort of tapping movement is simulated. The kinetic movement creates a shock effect, causing the particles (dust) to fall from the filter. These particles then go into a transport system. This could, for example, be a valve or a worm shaft that transports the dust. Depending on the purpose of the filter system, the product can be further processed. In the event that the product is waste, it's possible to dispose it.

Dust filter installation with pulse valves

Function of the Pulse Jet Dust Filter System

The video shown below is owned by the company Filter Concept from India. This video describes in a short animation the operation of a dust filter installation with pulse valves.

Time-controlled and pressure difference

A dust filter installation with a Pulse Jet system is usually available in two variants: Time-controlled or pressure difference. With time-controlled, the pulse time and pulse duration can be set manually. This method requires that the optimal setting for the dust filter installation must be checked regularly.

If the installation has a pressure difference measurement, so-called delta-p, the installation takes into account the pressure between the supply flow and discharge flow in the installation. If this difference is too large, it means that the filter bags are full of dust. To improve this, the pulse valves are activated to blow clean the filter bags. The time between each pulse is automatically regulated.

Applications Dust filter installations

Dust filter installations offer a wide range of applications. The filters are available on the market in many different diameters, lengths, materials and passage sizes. This variety means that a filter can be produced for every type of material, from dust to fibers. Dust filter installations can be found in a wide number of industries, such as the food industry, petrochemical industry, paper industry, wood industry and heavy industries such as cement, iron, coal and stone. In each area there are often different phases of the production process where filter installations have different purposes. That is why many factories have multiple dust filter installations for various applications.

As a result, in recent years much more attention has been paid to how to maintain these installations properly and sustainably. They are often large, prominent parts that take up a lot of space indoors or outdoors. In addition, due to their continuous operation, they have a great influence on the quality of the production process and the working environment of employees. With a continuous flow of air and the pulsing of the dust filter valves, the installations often consume more energy than expected.

Energy usage

Where is the energy consumption in Pulse Jet Baghouses? There are a number of components that cause the movement of airflow and particles. First of all, there is the vacuum pump that starts the air flow. This vacuum pump is mounted at the end of the pipe and is located directly next to the dust filter installation. The vacuum pump creates a continuous flow of air that sucks in the particles. This flow of air can vary in diameter depending on the product and the quantity. Due to negative pressure, the air moves towards the pump. This negative pressure will be low for light particles and higher for heavier parts.

In addition to the pump, many dust filter installations contain a fan in the filter housing section. This fan ensures that the air moves through the filter housing and not all parts want to go through the same filters. This flow also ensures distribution and separation of the particles. In larger filter installations, this fan has a large diameter and therefore has a high power level. When filter cloths start to become full, the fan will work harder to keep moving the air that cannot pass through the filter cloths easily. This makes cleaning the filters essential.

The most important energy consumers are the pulse valves that cause the air pulse to clean the filters. The savings with pulse valves can also be seen here. These pulse valves use compressed air at usually 4-6 bar and give a pulse for a set time to fill the filters with air. Compressed air is a widely used and widely available energy source. However, compressed air is an inefficient source of energy to produce. Air is widely available, but to get compressed air, this air must be compressed. This process, plus possible risk of leakage in the factory's air transport, makes compressed air an inefficient energy source.

Mac Valves Pulse Valve |

Diaphragm valve with double membrane |

Compressed air

Compressed air is air that is compressed, usually by a compressor. Air, unlike liquids, is compressible. The compressor compresses the air by reducing its volume. Compressors are available from different manufacturers and there are also several ways to compress air.

Example of an Atlas Copco compressor

To make compressed air, the air must be compressed, and subsequently this air is stored in an air buffer. This could, for example, be in the form of a buffer tank. Then, compressed air is released back into the atmosphere through a mechanical system, by a valve allowing it to flow into the atmosphere or into a cylinder. Because the air from a cylinder also enters the atmosphere via the exhaust, there is no regeneration of this energy. In other words, compressed air is for single use and therefore its efficiency is low compared to electrical or hydraulic systems.

The advantages of compressed air are that it is easy to generate, clean and cheap to purchase. In addition, a lot of compressed air has traditionally been available in factories, which means it will still be a widely used energy source for a long time to come. There are also improvements that can be achieved in the field of energy consumption.

Energy saving

With the Mac Valves Pulse Valves you save compressed air on your dust filter installations. In addition, your installation cleans better and the installation is therefore more maintenance-free. We briefly explain how this is possible here.

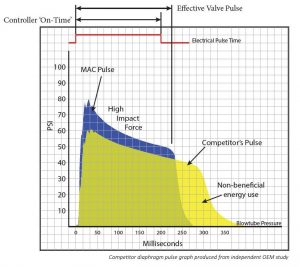

The energy saving comes from the better pulse that the Mac Valves pulse valve provides to inflate and deflate the filter. Since many filter installations are still equipped with valves with membranes, we compare these with the Mac Valves Pulse Valve. The difference in pulse is depicted in the graph below of a Mac Valves Pulse Valve compared to a diaphragm valve.

Pulse graph time versus pressure in PSI

As can be seen, with the same inlet pressure for both valves, the pressure peak with a MAC Valves pulse valve is higher than with the membrane technique. This is because a MAC Valves pulse valve does not have a continuous leak when opening. In addition, the opening and closing of the slide is faster than with a membrane technique. This allows a filter to be filled earlier and faster and also emptied earlier and faster. We will now explain the reason for this by the differences between a MAC Valves pulse valve and a valve with a membrane.

Differences between MAC Valves Pulse valves and diaphragm valves

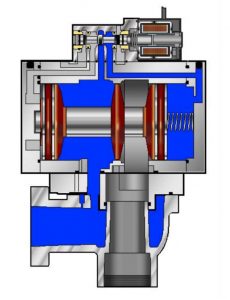

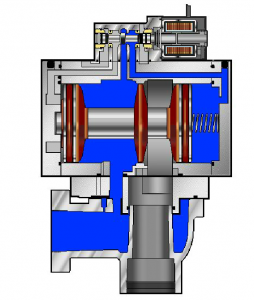

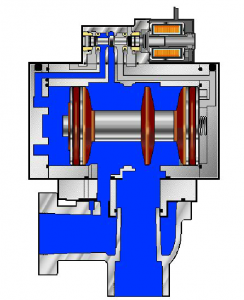

MAC Valves Pulse valve cross section |

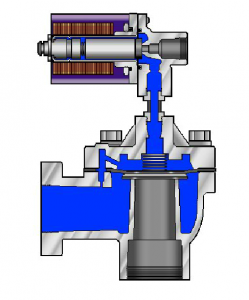

Diaphragm valve cross-section |

Above is the cross-section of a diaphragm valve with a single diaphragm and a pulse valve from MAC with a slide. As can be seen, both are on the same base plate. This makes them one-to-one interchangeable. The blue in both cross-sections is as air flows in the closed position. Firstly, we will further explain the operation of a diaphragm valve and then how a MAC Valves Pulse Valve works.

Diaphragm valve operation

With a diaphragm valve, the air enters and goes through a small passage, the bleedhole (see image above), to the top of the diaphragm. The space above the membrane is filled with the compressed air from the inlet. In addition to the pressure, there is also the mechanical spring that holds the membrane on the seat. Due to the larger surface area where the pressure acts at the top of the membrane and the smaller area where the pressure acts at the bottom, the valve remains closed.

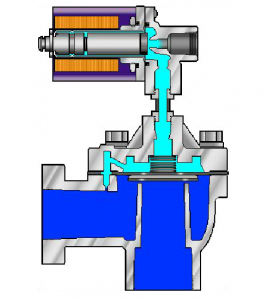

As soon as the pilot valve is energized, the air pressure at the top of the diaphragm will be blown to the atmosphere. See image below for the opened position. The pilot valve is energized and the stem moves away from the seat. This allows the air to escape and the membrane to rise. A continuous flow of air continues to escape into the atmosphere through the bleedhole. This ensures that the filter can never reach the inlet pressure. Due to the continuous leak, some of the air is lost and the pressure to the filter housing is lower than the inlet pressure.

The moment the pilot valve closes, the pressure above the membrane will build up again through the bleedhole. The time it takes to fill this volume until the force of pressure on top of the membrane is greater than below it is the time of closure. This takes longer than opening the valve. This shows that after the electrical signal goes out, there is still a period of time before no more air goes to the filter.

Operation of MAC Valves Pulse valves

A MAC Valves pulse valve works with a moving slider. This aluminum slide is bonded with rubber in the MAC Valves rubber factory (Great Lakes Rubber). This connection makes a slide optimal for good sealing and a long lifespan. The slide moves back and forth through a 5/2 pilot valve. This pilot valve changes where the pressure is, the two positions can be seen in the images below. The pilot valve ensures that the control air is either to the left or right of the slide. This causes the valve to close or open.

In addition, there is a built-in spring for safety. This ensures that the valve always closes again when the air pressure drops in the event of a malfunction. Because the pilot valve has the large air flow, true MAC Valves is known for, the slide moves back and forth quickly. Also, after switching, air is no longer blown into the atmosphere, so that the maximum pressure can be reached.

In terms of air flow, a MAC valve is optimized to initiate the flow as quickly as possible. The first air already comes from the buffer of the pulse valve and has to overcome less resistance. The slide has the special rubber combination that MAC Valves is known for. The inside of the rubber is soft while the outer edge is hardened. This ensures a tight fit, as well as smooth movement over the inner edge of the valve. In the valve housing, all parts over which the slide moves have been additionally finished for a smooth surface. This ensures smooth movement and a long service life.

|  |

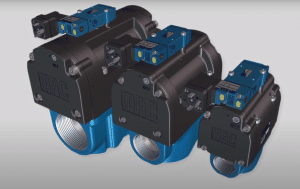

Different variants

The above valves are equipped with an electric pilot valve for the fastest possible operation. In addition, there are cases where the control valve is incorporated externally in a cabinet. This is usually to protect the control valve against contamination of the ambient air. This has to do with the open connection due to the principle of a diaphragm valve. In these cases, MAC Valves pulse valves can be mounted directly on the valve, as they are not sensitive to this contamination.

Another reason to install a pilot valve in an external cabinet is if the environment must be ATEX safe. ATEX stands for ATmosphères EXplosibles. This happens in environments where there are substances or gases that can ignite or explode. In this case you want to prevent a spark from arising that will cause an ignition or explosion. In the meantime, the MAC Valves Pulse Valve is also available with ATEX solenoid. This allows a MAC Valves pulse valve to be placed on the filter at the same time as the pilot valve. The big advantage of having the pilot valve directly at the filter is the speed of opening and closing. An extra pipe to a cupboard is an extra volume. This volume will influence how fast the valve is both when opening and closing.

MAC Valves pulse valves with Atex certification

Sizes

In terms of sizes, the MAC Valves pulse valves come in 4 different ones. The PV03 for 3/4″ and 1″ pipe diameters, the PV06 for 1 1/2″ pipe diameter, the PV09 for 2″ pipe diameter and the most recent addition is the PV12 for 2 1/2″ and 3″ pipe diameters. The MAC Valves PV12 has a vertical design to keep the valve stroke shorter. This allows the air to quickly reach the filter bags.

Savings MAC Valves Pulse Valves

As mentioned at the beginning of this article, the MAC Valves Pulse Valves offer savings. We will discuss these further below.

Energy saving

Energy savings and the energy used by pulse valves have been discussed before. The savings are mainly due to the following three advantages:

- Strong first pulse

- Short waste time

- No leak of leakages

Strong first pulse

The strong first pulse results from the rapid movement of the sliding shaft. This starts the flow of air quickly and also allows the entire flow to move quickly. In addition, there is no leak across the pilot valve, so full pressure is used. This allows the filter bags to fill quickly and expand. If there was previously too little pressure in the filter bags when they were clogged, this can now improve with the higher pressure. If the pressure was previously sufficient, this makes it possible to reduce the pressure. Reducing the pressure saves the compressed air required to achieve the output pressure.

Short waste time

Moving the slide back through the pilot valve is faster than with other techniques. This causes the power to drop quickly. Due to this faster loss of power, the valve will use less air during a cycle. Since the MAC Valves pulse valve does not unnecessarily blow air into the filter bags, the vacuum will empty the bag more quickly.

Due to the strong first pulse and the faster closing of the air flow, the filter bag expands faster and returns to its original shape faster, creating the desired knocking effect. This strong knocking effect ensures that more product falls from the filter bags. This allows less regular pulsing. See below images from a dust collector of a customer comparing rows of diaphragm valves with the MAC Valves pulse valves.

Both the arrival time and the departure time ensure better cleaning. With a pressure difference measurement, the so-called delta-p, this difference may be larger. If the filter bags are full, the valves will pulse more often. As soon as the bags can no longer be cleaned properly, the installation continues to pulse.

No leak of leakages

As previously indicated, a MAC Valves pulse valve has no leakage to the atmosphere when the valve is open. This is due to the closed pilot valve which moves the slider. Where a diaphragm valve operates with an identified leak, MAC Valves has chosen to eliminate this leak. This leak is also an unnecessary expense, as this energy is not used in an optimal way.

Due to the design of a MAC Valves pulse valve, wear is a minimal factor. The slider is a rigid part that slides on a flat surface. The material does not move flexibly, which makes the wear effect null. With a diaphragm valve, the rubber is moved twice during each cycle. Due to the forces of this flex, the rubber is continuously exposed to the risk of deforming or tearing. With rubber membranes, temperature also influences how the rubber undergoes natural wear. This can cause small cracks to occur. These small cracks usually go unnoticed until maintenance takes place. This is because they have no influence on the operation of the filter. However, these leaks are a continuous flow of compressed air that is lost, which is often the biggest cost.

Compressed air leaks are often unnoticed major cost items, both in the valves and in the supply lines. A small leak can quickly cost thousands of euros per year.

Uptime

Uptime is the time that a dust filter installation can continue to operate per year. The higher this value, the less maintenance was required. If large leaks occur in the pulse valves, the pressure will no longer be sufficient for the installation. The installation will be stopped to repair the leaks. Only then can the installation be started again.

In addition, the filter bags may become too full with the product and become clogged. This means that the pulse valves can no longer clean the bags and the bags must be manually cleaned or completely replaced. Since there are usually many filter bags on an installation, this is a time-consuming job. In addition, it is potentially a dangerous job, which comes with the necessary risks. If the dust filter installation also has to pulse relatively often, the filters also wear out faster. This makes the filter bag replacement interval shorter.

With MAC Valves pulse valvesm there is no chance of leaks due to wear, thus the installation can continue to work. In addition, the more powerful pulse will clean the filter bags better, so that they do not clog. Due to the less frequent pulsing with MAC Valves pulse valves, the replacement interval is longer. This ensures longer uptime per year and more production, which equals more profit. This extra production will increase sales and therefore increase profits.

Less maintenance

The lifespan of the MAC Valves pulse valves is very long due to the low risk of wear. The MAC Valves pulse valves have standard Viton rubber parts. This rubber has a wide temperature range, is wear-resistant and can withstand contamination from the supply line. This means that the maintenance interval is much longer than with other pulse valve techniques. This ensures a lower cost of ownership.

Additionally, it is possible to replace the filter bags less regularly thanks to the MAC Valves Pulse Valves. This offers a major advantage in terms of working time and labor intensity, in addition to the purchase price of the filter bags. Dust filter installations are often placed in places where they are difficult to reach. This can be on the roof or, for example, in the open air. This increases the employee's risk of possible disasters. Since maintenance of the filter installation becomes less frequent thanks to the MAC Valves pulse valves, this saves working hours and reduces the risk of injury.

Product efficiency

Filter installations should also be adjusted as efficiently as possible. You want to collect all the product particles in the installation to process it. This works better if you can adjust the cleaning of the filter bags. With the help of better cleaning, more product can come off the filter bags per cycle. A filter bag should always have a small layer of product on it. This ensures that the other product can adhere properly. You want to prevent the filter from being too clean. The rapid movement of the filter bag, caused by a MAC Valves pulse valve, causes the excess product to fall off. The necessary layer can be adjusted properly and consistently with the pulse time and inlet pressure.

Due to the aforementioned higher uptime and the improved efficiency of the dust filter installation mentioned here, this helps the production of the product. The constant switching times of the MAC Valves pulse valves also ensure the same effect from cycle to cycle. As soon as it appears that the membrane valves can no longer clean the filter bags properly, the product will stick to the filter bags. When removed manually, often this product will no longer be usable.

Longer filter lifetime

A dust filter contains many parts that limit its lifespan if it is heavily contaminated. As soon as filter bags fail, the product will pass through the filter bags to the pump. This will not do the vacuum pump any good in terms of lifespan. In addition, if the fan is dirty, the fan should have worked, which means it requires a higher current. During long periods of operation under high current, wear on this part is greater.

In addition, the lifespan of the filter bags and pulse valves has already been discussed in detail. All these components together form a large part of the lifespan of the entire dust filter installation.

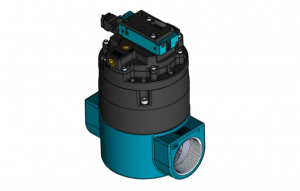

Easy use and installment

The MAC Valves pulse valves have been developed in such a way that they can be installed directly in an installation on the existing buffer volumes or pipework. This makes it easy to upgrade the dust filter installation without any adjustments. MAC Valves once started to support customers in this area with existing large flow valves. In that case, these were the well-known ones 57, 58 and 59 series of valves, which work on the same sliding technique. The disadvantage of this solution was that it's more difficult to convert. After the introduction of the specially designed pulse valves, conversion is simple in most cases. This is due to the same base plate as the valves used or the option to attach to existing base plates via an adapter plate. See both designs below. On the left is the design with the base for existing pipes. On the right the design in which an adapter plate is placed. This can be done on a buffer tank or on a normal base.

|  |

Assembly is done with 4 bolts for mounting the valve on the base plate or on the adapter plate. This makes mounting easy.

Besides installation, there is also an advantage to the MAC Valves pulse valves that is not available to diaphragm valves. To find out whether a valve is still switching, you can operate the pulse valve with the so-called manual override. This manual override is actually a manual control for the valve.

Green impact

The MAC Valve pulse valves are good for the environment due to their technical advantages. They use less compressed air and therefore energy and operate at a lower power. The dust filter installations become more efficient due to better cleaning. For example, dust filter installations intended to clean the air will operate better. Dust filter installations to clean flue gas will be able to remove more particles from the air. All this ensures a better impact on nature, as these particles do not enter the outdoor air. CO2 will be reduced by less hard-working vacuum pumps and fans. See below an example of a factory where the air quality in the working environment has greatly improved thanks to the MAC Valves pulse valves.

Newly built dust filter installations with MAC Valves pulse valves

Compared to membrane technology, the MAC Valves Pulse Valve is still a new technology for dust filter installation manufacturers. However, many manufacturers are already supplying new dust filter installations with the MAC Valves pulse valves. See for example Dynamo Dust Collectors, where they can be ordered in complete package with MAC Valves pulse valves. Moreover, most dust filter installation manufacturers are aware of the technology and can optionally supply it to the installation. Especially now that large multinationals have indicated that they want to use the MAC Valves pulse valves as standard on new and existing installations, it is becoming increasingly easier. Of course, for many companies, converting to the new technology is the first and most important step. In most cases, the conversion can be paid for with a quick ROI. We are keen to help you with this. You can contact one of our specialists without obligation via sales@astro.nl.

Downloads

The different valves sorted by port size:

3/4″ – MAC Valves Pulse Valve PV03

1″ – MAC Valves Pulse Valve PV03

1 1/2″ – MAC Valves Pulse Valve PV06

2″ – MAC Valves Pulse Valve PV09

2 1/2″ – MAC Valves Pulse Valve PV12

3″ – MAC Valves Pulse Valve PV12