- 0172-424247

- sales@astro.nl

- Eikenlaan 235, 2404 BP Alphen aan den rijn

Saving energy in the heavy industry can be done in various ways. Astro Controls supports and provides insights into opportunities for energy savings in your company.

Years ago we started improving the filling quantity on filling machines. To illustrate, when filling beer and soft drinks it is very important not to overfill or fill too little. Then, we moved to improving the energy consumption of compressed air applications. That's how the Mac pulse valve is developed. The pulse valve is designed for production locations of heavy users, to optimize compressed air usage and to minimize compressed air consumption.

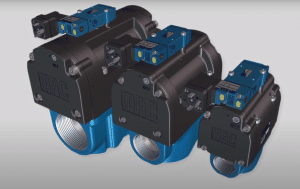

We're also replacing pneumatics and increasingly replacing hydraulics, with the help of electromechanical solutions. This way, pneumatic cylinders, and all components around them, are being replaced by electric cylinders.

Take compressed air for example. A very inefficient form of energy, with a low efficiency. Air is free, however, compressed air is far from complimentary. Our national government estimates the costs at approximately 2 cents per m3. These estimations are based on energy costs, depreciation of compressors and everything involved around it. Thus, there is much to be gained from the efficiency of electromechanical applications.

Hydraulics itself is an efficient form of energy, but it is subject to contamination in the event of leakage. It also requires much more maintenance than electromechanical applications.

Saving energy leads to both cost reduction and benefits for the environment.

Astro Controls supports your company in the field of labor savings in the industry. Cost reduction when it comes to labor is interesting. Additionally, the elimination of simple repetitive tasks is also important. It is more difficult to motivate employees for physically intensive, repetitive tasks. Robots have been offering great advantages for this for years. Robots can continuously perform one task well, repeatedly.

Astro Controls can support in this area with the Smart Collaborative Robots. These robots are easily to program, and are re-programmable. They are operated with a graphical interface and can be installed without programming knowledge. This eliminates the need for expensive programmers. This makes it possible to program without the help of the robot manufacturer.

If you do not want or cannot program the robot yourself, we can take care of that and give support. This is a possibility if you want a turn-key robot solution. We install and integrate the robot according to your wishes. Additionally, we can provide support when reinstalling the robot at a different location in your production facility. We also offer a training course for your staff - who would normally perform the physically intensive and repetitive tasks - and train them to become robot programmers. Due to the graphical interface, the threshold to understand this is really low. If needed, Astro Controls will always be there to support your company.

If you do not want or cannot program the robot yourself, we can take care of that and give support. This is a possibility if you want a turn-key robot solution. We install and integrate the robot according to your wishes. Additionally, we can provide support when reinstalling the robot at a different location in your production facility. We also offer a training course for your staff - who would normally perform the physically intensive and repetitive tasks - and train them to become robot programmers. Due to the graphical interface, the threshold to understand this is really low. If needed, Astro Controls will always be there to support your company.

More often than not, it is not desirable that a machine is completely built by one company. This is no longer viewed as "lean". Lean manufacturing helps you understand how to optimize your production processes. Thus you will get a clear picture of what is and what is not key in the production process. This can be done when building a machine, as well as for optimizing a production line.

Astro Controls is specialized in pneumatic systems, electromechanical applications and robotization. Our engineers, production and our factories have decades of experience. Often, we take the work out of the customers hands, by developing a complete solution and executing the assembly. We have the knowledge to manufacture a compact, complete pneumatic panel or switch box for your machine. In addition, we have all the parts to produce an economical, complete solution.

Furthermore, in the field of electromechanical applications, we can program and test the solution in advance. This makes it a plug and play solution for your machine.

As mentioned earlier, in terms of robotization, we work with a turn-key solution, including integration.

The biggest advantages of all these services, is that you do not have to educate and train employees for things that we can easily do for you. In addition, you are less dependent on your order portfolio, since you only pay for the moments you need the labor. Thus, your specialists do not have to perform other tasks to keep productive.

Are you curious about the possibilities? Please contact us and make an appointment without any strings attached.