[:nl]

Save energy on dust-filter-installations with MAC Pulse valves

De energiebehoefte is nog steeds stijgende en overheden doen er alles aan om deze te verkleinen. Dit moet zorgen voor een duurzame wereld en zorgt gelijk dat er bespaard wordt op energie. MAC heeft Pulsventielen voor stoffilterinstallaties die zorgen voor een grote energiebesparing door het verminderen van het perslucht verbruik. Deze besparing wordt hierna verder uitgelegd.

Introductie MAC Pulsventielen

Veel van onze klanten zijn al op de hoogte gebracht van de voordelen van onze MAC Pulsventielen als alternatief voor de veelgebruikte membraanventielen. Toen we hiermee in 2009 begonnen waren de voordelen vooral de volgende:

• Geen scheurende rubber membranen door het gebruik van een met rubber omgote schuifas

• Geen onverwachte en onbekende lekkages

Deze problemen zorgden voor veel ongepland onderhoud door verlies van druk en veel arbeid voor het vervangen van membranen op vaak ongelukkige locaties.

De membranen hebben een verwachte levensduur van circa 1 miljoen schakelingen. Dit betekent dat zeker bij hoogfrequent schakelen de membranen scheuren, nog voor het voorgeschreven interval van preventieve vervanging. Door het vervangen van de membraanventielen met onze MAC Pulsventielen,

die een veel langere levensduur hebben, worden de volgende resultaten behaald:

• Minder ongepland onderhoud

• Verruimen van het voorgeschreven preventieve onderhoud met een factor tussen de 5 en 10

Makkelijk uitwisselen op bestaande installaties

Toen de MAC Ventielen op stoffilterinstallaties voor het eerst werden geïntroduceerd, gingen we uit van bestaande ventielen uit onze range. Het nadeel hiervan was dat de filter installaties moesten worden aangepast om onze ventielen in te kunnen bouwen. Na de grote toename in aantal geïnteresseerde klanten is er daarom een speciale lijn ventielen beschikbaar gekomen die makkelijk zijn uit te wisselen.

Hiervoor zijn er de volgende twee opties:

• Compleet MAC Pulsventiel met dezelfde poorten als bestaande membraanventielen.

• MAC Pulsventiel met adapterplaat om het ventiel op het bestaande fitwerk te monteren.

Zie de afbeelding rechts voor het ontwerp met een aparte adapterplaat. Momenteel heeft MAC al veel adapterplaten ontwikkeld voor de verschillende ventielen in het veld. Voor de meest gangbare merken zoals Asco, Goyen, Turbo en Mecair zijn reeds adapterplaten beschikbaar.

Energy saving

Nadien zijn er zowel in Nederland als in de wereld veel klanten overgegaan naar het gebruik van onze MAC Pulsventielen. Door het toepassen in de praktijk en de nu jarenlange ervaring, is gebleken dat er nog meer voordelen zijn, ten opzichte van de membraanventielen.

Zoals u gewend bent van MAC Ventielen zijn dit de snelst schakelende ventielen op de markt. De MAC Pulsventielen hebben een grote doorlaat van 3/4 inch tot 2 1/2 inch (grotere doorlaten zijn nog in ontwikkeling), maar schakelen nog steeds razendsnel. In vergelijking met de membraanventielen, heeft dit voor de stoffilterinstallaties de volgende grote voordelen qua energiebesparing:

• De flow na het open schakelen gaat harder, waardoor de impactsnelheid op de stofdoeken hoger is

• De MAC Pulsventielen schakelen sneller af, waardoor er minder lucht verbruikt wordt per puls.

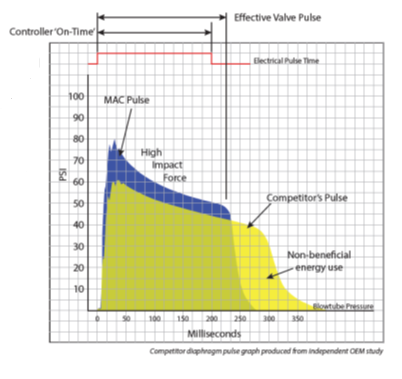

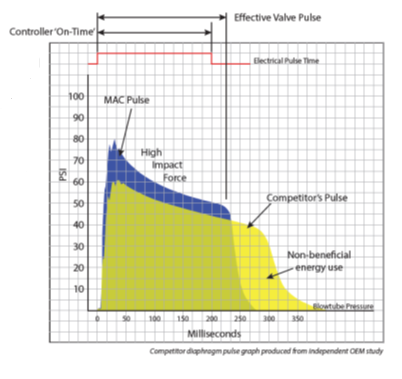

Deze vergelijking ziet u in de volgende grafiek:

Door de grotere impactsnelheid van de flow, worden de filterdoeken schoner geblazen. Aangezien het gewenst is dat er altijd nog een rest stof op de doeken zit, zorgt dit ervoor dat bij het gebruik van de MAC Pulsventielen er twee zaken aangepast kunnen worden:

Door de grotere impactsnelheid van de flow, worden de filterdoeken schoner geblazen. Aangezien het gewenst is dat er altijd nog een rest stof op de doeken zit, zorgt dit ervoor dat bij het gebruik van de MAC Pulsventielen er twee zaken aangepast kunnen worden:

• De druk van de gecomprimeerde lucht

• De intervaltijd tussen de pulsen kan verruimd worden

Door deze twee aanpassingen wordt het persluchtverbruik in uw installatie aanzienlijk verminderd, en daarbij bereikt u de energiebesparing die u voor ogen heeft.

Lucht is gratis, perslucht zeker niet

Perslucht is duur, perslucht op 8 bar kost circa 1,5 cent per m3. Dit is natuurlijk afhankelijk van het rendement van de compressor. Voor grote doorlaten, zoals die van de stoffilterinstallaties (3/4 inch tot wel 3 inch), betekent dit dat de kosten erg oplopen. Daarnaast zijn lekkages nog duurder, bij lekkages gaat er veel lucht verloren door een grote doorlaat. Een volledige lekkage op 7 bar van 1,5 inch (38 mm) in diameter, kost bijna € 1.000 per dag. Vandaar dat scheurende membranen, buiten de kosten van onderhoud, ook zeer veel energiekosten met zich meebrengen. Een energiebesparing is hier daardoor gewenst.

Als een ventiel in een stoffilterinstallatie minder kan pulsen, betekent dit dus ook minder luchtverbruik per dag. Daarnaast is het luchtverbruik per puls bij een MAC Pulsventiel minder dan bij een membraanventiel, waardoor het stoffilter zelfs bij hetzelfde aantal pulsen al minder lucht verbruikt.

Return on Investment

Onze sales engineer komt graag bij u langs om aan de hand van uw gegevens een verdienmodel te genereren. In dit model komen alle technische gegevens terug van uw huidige installatie en wat we voor u kunnen besparen. Vervolgens komen we hierna met een ROI (return on investment), welke we duidelijk en snel aan u kunnen tonen.

De praktijkvoorbeelden leren dat de ROI regelmatig onder de 12 maanden ligt, vaak zelfs binnen de 6 maanden.

Real life examples

De voorbeelden uit de praktijk zijn legio, en er komen steeds meer voorbeelden bij. Veel bedrijven zijn natuurlijk niet bereid om de resultaten die ze behalen te delen, aangezien ze hierbij zelf het voordeel houden boven de concurrentie. Gelukkig is dit niet altijd het geval en bespreken we hieronder graag drie voorbeelden van bedrijven die publiekelijk onze MAC Pulsventielen onderschrijven.

JD Norman, UK

Bij JD Norman in Engeland staan verschillende stoffilter installaties met membraanventielen. De video hieronder geeft u een goed beeld van hoe de situatie was en hoe deze nu is met onze MAC Pulsventielen op de eerste stoffilterinstallatie die is omgebouwd. De membraanventielen pulsten elk om de 10 seconden met een pulstijd van 1 seconde, en nog was de luchtstroom door het filter slechts 12 km/uur. Na installatie van de MAC Pulsventielen waren deze door de efficiëntere puls als volgt:

Elk ventiel pulst elke 300 seconde met een pulstijd van 0,3 seconde, de luchtstroom door het filter was verhoogd tot 30 km/uur. Op deze manier werd een beter reinigingsresultaat met veel minder pulsen bereikt. Van 2 miljoen pulsen per jaar per ventiel naar ongeveer 70 duizend pulsen per ventiel per jaar.

[embedvideo type=”youtube” id=”m8rPPY7-Wb0″]

Cemex, Mexico

Cemex is één van de grootste groepen ter wereld in het leveren van grondstoffen voor de bouw. Over de hele wereld zitten verschillende productie fabrieken voor onder andere cement. Cemex heeft net als vele bedrijven op meerde locaties testen gedaan met de MAC Pulsventielen. Elk jaar maakt Cemex een plan voor de belangrijkste investeringen, en zoals veel productiebedrijven is het besparen op energie één van de belangrijkste doelen. Na de grote verbeteringen op het gebied van luchtverbruik zijn de MAC Pulsventielen de nummer één prioriteit voor de hele CEMEX groep.

[embedvideo type=”youtube” id=”zci6znbH–Q”]

Carpet Pad manufacturing, USA

Bij deze productieplant voor tapijt hadden de onderhoud medewerkers problemen met het reinigingseffect van de membraanventielen bij een aantal soorten stof. Hierbij liepen de filters vol en moest het stoffilter met de hand leeg gehaald worden, wat circa 4 uur duurde. Door de grotere snelheid van de flow door de MAC Pulsventielen, was dit geen probleem meer. In de onderstaande video onderschrijft het hoofd van de technische dienst de kwaliteit van pulsen. Daarnaast is er ook gefilmd vanuit het stoffilter met daarbij een duidelijk verschil in de puls van een membraanventiel en een Mac Pulsventiel.

[embedvideo type=”youtube” id=”hLPHugCbmKk”]

Bovenstaande succesverhalen kunnen ook voor uw installaties van toepassing zijn.

We komen graag de verschillen en voordelen aan u voorleggen. Hierna kunnen we toewerken naar een test, zodat we u in de praktijk kunnen aantonen hoeveel succes u kunt behalen.[:en]

Energy savings on Dust Collectors with Mac Pulse Valves

The world keeps increasing the demand for energy and governments are doing everything to decrease this. This should help to make the world more sustainable and also helps to save on energy costs. MAC Valves has designed Pulse Valves for Dust Collectors that help with the energy saving by reducing the need for compressed air. These energy savings will be explained after this.

Introduction to MAC Pulse Valves

Many of our customers are already aware of the benefits that the MAC Pulse Valves have as alternative to the much used diaphragm valves. When we started with these valves in 2009, there were some major advantages:

• No leaking rubber diaphragms because of the use of the rubber bonded spool design

• No unexpected leakages

These issues with diaphragm valves caused a lot of unscheduled maintenance because of the lost of pressure and lots of maintenance to replace diaphragms at sites that are difficult to reach.

The diaphragms have an expected lifetime of about 1 million cycles. This means that in applications where the valves shift frequently the diaphragms already tear before they have to be replaced during scheduled maintenance. By replacing the diaphragm valves with our Mac Pulse valves, which have a much longer lifetime, the following results are accomplished:

• Less unscheduled maintenance

• Longer interval between scheduled maintenance

Easy interchange on excisting Dust Collectors

When we first started with MAC Valves on Dust Collectors, we started with excisting valves from our range. The disadvantage of this was that the excisting Dust Collectors had to be adjusted to fit our valves. After the big interest from customers, a special line of MAC Valves has been designed. These are easier to install on existing Dust Collectors to replace the diaphragm valves. We have two different options:

• MAC Pulse Valve with Mac Base Plate that fits onto excisting piping

• MAC Pulse Valve with an adapterplate to fit onto the diaphragm valve body

See the picture on the right to see a MAC Pulse Valve with an adapterplate that mounts onto an excisting body of a diaphragm valves.

MAC Valves already designed many different adapter plates for the valves found in the field. To replace for instance Asco, Goyen, Mecair, Turbo and other brands.

Energy savings

After these valves were released many customers in both the Netherlands and in the rest of the world have changed to using the MAC Pulse Valves.

By using the valves on different sites and the many years of experience in the field, it turned out there were even more advantages in comparison with the diaphragm valves.

As you are accustumed of MAC Valves, the Pulse Valves are the fastest shifting valves available on the market. The MAC Pulse Valves have an orifice of 3/4 inch up to 2 1/2 inch (larger sizes are in develelopment), but still shift at high speed. In comparison with the diaphragm valves this will have the following major advantages:

• The flow of the valve is energizing faster, therefore the impactspeed is higher

• The Mac Pulse Valves are de-energizing faster, therefore they use less air per pulse

The comparison can be seen in the following graph:

Because of the high impactspeed of the flow, the MAC Pulse Valves have a better cleaning effect. Because it is usually normal to have still some dust on the bags, the better cleaning brings up the following possibilities:

• Adjust the pressure of the compressed air

• Change the intervaltime between two pulses

As you can imagine, these adjustment bring big advantages in the consumption of compressed air. And help with the energy savings you like to accomplish.

Air is free, compressed air definately not

Compressed air is expensive, compressed air at 8 bar cost roughly 1,5 cent per m3. This is ofcourse depending on the efficiency of the compressor. For big orifices, like the valves used on Dust Collectors (3/4 inch upto 3 inch), it means the cost can get high. Beside that the leakages are even more expensive. With leakages a lot of compressed air is lost into the atmosphere. For instance a leakage at 7 bar of 1,5 inch (38 mm) in diameter, this will cost around € 1000 a day. Therefore diaphragms that tear, outside the cost of maintenance, also cost a lot in terms of energy. An energy saving is therefore desirable.

When a Pulse Valve in a Dust Collector is able to pulse less, it means that the valve will also use less air during the day. Also the air consumption of the Mac Pulse Valve is less per pulse than a diaphragm valve. Because of that, the Dust Collector will use less air, even with the same amount of pulses.

Return on investment

Our representative could come around to show you, according to your data, how much you can safe with our solution. All your technical specification from the Dust Collector will come back and we’ll show you how much you can safe. This file also gives us the possibility to show you a ROI (return on investment) to quantify the saving.

From our experience at customers, the average ROI is within 12 months. We even have plenty of examples where the ROI is even within 6 months.

Examples

The examples from the industry are wide available and more keep coming. Our representative will gladly talk to you about this. Unfortunately, many of the companies we help are not eager to share the savings they have accomplished. This way they can keep the advantage over the competition.

Luckily there are still companies that agreed to share the information with other companies. These have been made publicly with the approval of the companies and they agreed to work with us on public videos.

Below we’ll discuss three recent examples and what their experience is with the MAC Pulse Valves.

JD Norman, UK

At JD Norman in England they have different Dust Collectors with diaphragm valves. The video below will show you a good view of how the situation was before the MAC Pulse Valves and also after the installation. The diaphragm valves were pulsing every 10 seconds with a pulse time of 1 second. With that setting the flow of the dust through the filter was only 12 km/hour. After installation of the MAC Pulse Valves, because of the more efficient pulse, they had the following result: Every valve now has a pulse every 300 seconds and also a pulse time of only 0,3 seconds, and also the flow of the dust through the filter was raised to 30 km/hour. This resulted in a better cleaning result with fewer and shorter pulses. They went from 2 million pulses per valve to about 70 thousand pulses per valve per year.

[embedvideo type=”youtube” id=”m8rPPY7-Wb0″]

Cemex, Mexico

Cemex is one of the biggest groups in the world for supplying raw materials for the building industry. They have plants all around the world, for instance for producing cement. Cemex is originally a Mexican company and the headquarter is located near the Mexican distributor of MAC Valves, this distributor is Grupo Kopar. Cemax has tested the MAC Pulse Valves at different locations. Every year Cemex makes a plan for future investments, and as many companies energy savings are the main goal. Therefore after the succesful tests with the MAC Pulse Valves they made this the number one priority for the complete group.

[embedvideo type=”youtube” id=”zci6znbH–Q”]

Carpet Pad manufacturing, USA

At this production facility for carpets the maintenance department had issues with the cleaning effect of the diaphragm valves for different type of carpet. The Dust Collectors were clogged and then the Dust Collector had to be cleaned by hand, which took them about 4 hours. Because of the high speed of the flow by the MAC Pulse Valves, this wasn’t an issue anymore. In the below video you can see someone from maintance that the quality of the pulses explains. In the same video you can also see a recording inside the Dust Collector where you can clearly see the difference in the pulse for a diaphragm valve and a MAC Pulse Valve.

[embedvideo type=”youtube” id=”hLPHugCbmKk”]

These are just a few companies that were willing to work with MAC Valves to spread the information towards the competition. Many times they do it to help other companies that also have a hard time to find ways to reduce the use of energy.

We would like you to invite us to explain you the differences and the benefits again and more clear. We also would like to help you to set up a test, because we would like to prove to you how much success you can achieve.[:]